Media

Key highlights, industry news, insights, and expertise around the world of logistics

Logistics and supply chain trends for 2022

Global supply chains are highly complex and involve numerous stakeholders often located in different countries and, sometimes, even on different continents. This makes the chains extremely fragile and vulnerable to disruptions. The outbreak of the COVID-19 pandemic in 2020 and followed by nationwide lockdowns across the globe have drastically impacted supply chains, changed how logistics processes are handled and accelerated certain developments and innovations due to the new circumstances.

Many shippers and transport providers have been forced to rethink their supply chain strategies as market conditions evolve. Supply chain solutions have been around for decades as they ensure the world stays connected no matter what. However, the way they are managed has been evolving over the years making them less manual, more efficient, and resilient. With COVID-19 spreading globally, the transformation of supply chains has been significantly boosted.

In this article, we will look at some latest trends in logistics and supply chain management which have been developing quickly and should be closely observed and adopted to stay ahead of the game maintaining a successful, growing, and sustainable business.

What are the top trends in the logistics and supply chain industry in 2022?

1. The rise of e-commerce

COVID has obviously accelerated the growth of e-commerce. While people were stuck in their homes, the only way to easily obtain goods was via the internet. And as consumers realize the benefits and the comfort of online shopping, the demand for e-commerce products will remain high. And this does not only apply to B2C but also to B2B businesses in the future as research by Garner shows. It is estimated that 80% of B2B sales interactions will be done digitally by 2025.

And as in e-commerce, one of the most important factors for success is the customer’s experience, which is hugely based on the efficiency of the supply chain management, therefore companies need to focus on seamless fulfillment processes. It is the only way to ensure that products reach the consumers as quickly as possible and that the ever-changing consumer demands are met in time.

2. Building resilient supply chains

While the pandemic caused large supply chain disruptions, on the one hand, it increased the customers’ desire to receive orders even quicker. Consequently, retailers have realized that they need to focus on creating robust, adaptive, and agile supply chains and fulfillment processes to ensure a continuous and seamless flow of goods. Compiling a clear contingency plan, building a strong collaboration among stakeholders and global networks as well as localizing and diversifying own products and sources are the main capabilities needed to ensure supply chain resilience. A well-established supply chain set-up will enable a company to react to any type of global disruptions faster than the competition, ensuring excellent customer experience.

3. Timeliness of last-mile transportation

Certain changes in the overall economic and trade landscape have accelerated consumers’ shopping habits and their delivery expectations all around the world. Some retailers, in particular, wholesalers such as grocery stores, have reacted quickly and upgraded their last-mile delivery. Hence, to stand up to the competition and meet customer expectations, shippers should now invest heavily in sophisticated and efficient distribution and complex last-mile delivery models resulting in even higher customer satisfaction. This is not an easy task for logistics companies in Dubai, UAE, or other MENA countries due to infrastructure challenges like the absence of street addresses. To tackle this logistical challenge, conveniently located warehouses, real-time monitoring of shipments and advanced technology are crucial tools to implement to ensure customer satisfaction through a reliable last-mile delivery.

4. Increased focus on reverse logistics capabilities

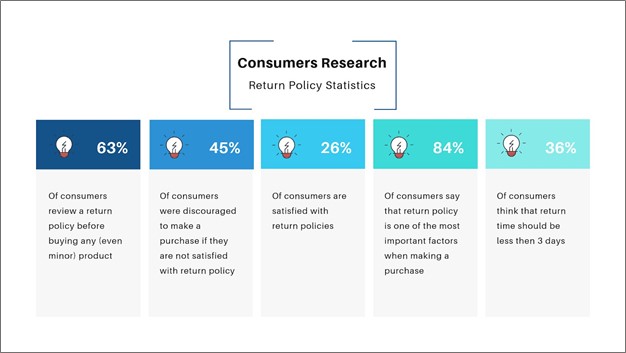

Research shows that customers return up to 30% of their online orders. This means that returning goods from their destination to their point of origin, called reverse logistics, must be provided. Growing expectations of replacement or refund of returned products is a challenge supply chain companies need to deal with. Managing reverse logistics well will be a great competitive advantage as it influences customer satisfaction remarkably.

The ideal scenario is to be able to handle items being shipped back as seamlessly as they are sent out. But there are a great many challenges to this process. For one, businesses need to be able to predict which items are likely to come back up the supply chain, and where they are most likely to arrive. If the cost of this outweighs the value of the item, companies lose money. It’s also important that the goods themselves don’t get lost in the process.

Source: DataArt

Taking consumer insights into consideration, when designing reverse logistics strategies and return policies, is one of the best bets companies have to stay relevant in the trade business.

5. Adoption of the latest automation technology

The question in logistics is always how processes can be streamlined and become more efficient in order to shorten lead times and achieve cost optimization. One of the answers is automation, which has found its way into warehouses. Artificial intelligence-based technologies and robotics automate administrative tasks and plan fulfillment processes as well as minimize human errors. Drones and smart lockers will play increasingly crucial roles in facilitating last-mile deliveries and improving customer satisfaction. A report by Frost & Sullivan claims that the global warehouse automation market is expected to nearly double its size, growing from $14 billion in 2019 to $27.2 billion by 2025. The automated guided vehicles (AGV) segment is forecast to hit $4.6 billion while the autonomous mobile robot (AMR) segment is expected to reach $6.8 billion.

Smart parcel lockers are increasingly growing around cities all over the world. Pick-up lockers are secure, easily accessible 24/7, and a contact-free way to receive orders.

6. Supply chain integrations using Cloud Technology

The cloud industry, in general, has seen enormous success, with a compound annual growth rate of 19.1% leading to an expected market size of US$1,251.09 billion by 2028. In logistics management, it has been evolving for some years already but has seen a boom from 2020 due to COVID-19. Logistics and supply chain solutions providers are catching up in adopting cloud computing in supply chain management, with 50% of logistics service providers already tapping into cloud-based logistics and 20% ready to migrate their on-premises solutions to the cloud.

As prices for cloud technology are becoming more affordable, it is likely that logistics SMEs will be the main users for this development in 2022. Lower costs also enable smaller companies to purchase advanced software such as data analytics, ERP, inventory management, CRM, and accounting software helping them to significantly upgrade their business operations.

7. Sustainability in the logistics industry

The pandemic has given sustainability across various industries a new pulse bringing it more into the focus of governments, companies, and end-consumers. Customers nowadays pay more attention to the sustainability of a product including the way the item is being manufactured, processed, and transported. Hence, the global sustainability market is booming, and according to Globe News Wire, it will be worth 36.6 billion USD (132 billion AED) by 2025. Inevitably, as awareness increases and preferences shift, so too will the operations that help bring products and services to billions around the globe. That’s why, companies who re-evaluate their supply chain processes with more focus on making them more efficient, greener, and carbon-neutral will have a competitive advantage and are more likely to build a loyal customer base throughout 2022 and beyond. Implementing sustainability strategies and practices should be considered an investment that will contribute to a business' long-term profitability, as experts say.

Do you wonder how you can start your sustainability transformation without spending a fortune? Read our article “How you can make your logistics operations more sustainable” providing a lot of tips on how to become greener as a player in the logistics and supply chain management space.

8. Qualified talent and drivers

Also belonging to the trends in supply chain and logistics management is the focus on qualified and experienced employees. As this article illustrates, the logistics industry is changing fundamentally, becoming more digital and tech-driven. To manage this transformation successfully, companies need to recruit talent with the right technical understanding and analytical skillset. It’s not only about finding and hiring new employees but also about training and developing the existing workforce to upgrade their capabilities. Some sources state that the qualification and skills of drivers in the Middle East, for example, don’t meet the benchmark set by Western countries. Driver shortage and lack of driving skills is a global phenomenon for a few years. However, for the industry, the level of driving skills makes a huge difference to its overall performance as it impacts fleet efficiency. Due to a Shell report, independent tests indicate that highly skilled drivers can reduce fuel expenses by between 5% and 20% on average and subsequently lower costs associated with the wear and tear of vehicles.

Hence, road freight carriers should not try to save costs when it comes to developing their workforce. Fair working conditions, as well as professional and sufficient trainings for the drivers, will influence the overall performance which is important in a highly competitive market with tight margins. Overall, investing in in-house resources will be essential for maintaining a competitive advantage. However, strategies to attract and retain talent are also changing as traditional approaches may not be as relevant to future supply chain needs.

9. Localization of supply chains

When COVID-19 hit the markets unexpectedly and global supply chains got interrupted, many companies in the logistics industry changed their global strategies to local ones, realizing great benefits coming with it. As you no longer depend on freight coming from abroad, border closures due to special events such as a global pandemic are no longer a risk to your business operations. In addition, lead times are more accurate and easier to control as distances between the suppliers and customers are located close to each other. Moreover, your business operations become more ecological as you reduce your carbon footprint by avoiding emissions-heavy international freight movements.

Considering the positive impact local sourcing has, it is likely that local expansion remains a trend in logistics and supply chain management in 2022.

10. Innovation through digitization

Digitization is widely innovating industries by automating and accelerating internal and external processes and utilizing data to provide visibility and reduce inaccuracies. Without digitization it will be nearly impossible to establish an end-to-end robust supply chain, enabling comprehensive efficiencies within the industry. The good news is that new supply chain technologies are already being developed using existing tools including Blockchain, Internet of Things (IoT), artificial intelligence, automation, and robotics, as well as digital supply networks (DSNs).

DSNs can significantly contribute to disaster-proof supply chains. A DSN connects virtually all parties involved in a supply chain ecosystem via a handy online platform. By sharing, analyzing, and viewing fundamental information and data, real transparency and effective communication flow along supply chains are enabled. This way cooperation between sellers, buyers, suppliers, freight forwarders, transportation hubs such as ports and airports, can be massively improved and appropriate decisions such as changing suppliers, shifting volumes, or changing transport routes can be taken based on real-time facts, all of which are critical in times of stress and shortages like during the COVID-19 outbreak.

Continuous evolution for 2022 and beyond

Every year, we are set to see evolutions and innovations in our global supply chain. Technology, obviously, plays a huge role in these advancements. Agile adaptation can offer businesses competitive advantages not only against the competitors in the market but also against the ever-increasing consumer demands. The disruptions we are experiencing also deserve some credit as it incredibly influences the resilience strategies we are adopting right now. On a hopeful note, we can look at these supply chain ‘Opportunities to Shine’ as fuel to enhance customer centricity exponentially.

RSA Global is a digital supply chain solutions provider based in the UAE. Our cost-effective logistics technology offers intuitive 360° digital solutions to our customers. ClickSC (Click for your Supply Chain) is our freight management system and first API tool while ClickRF (Click for your Road Freight) is our advanced transport management system, both of which are integrated with our proprietary WMS, ClickWM (Click for your Warehouse Management System). This set of digital platforms for international freight, e-commerce, road freight and smart warehousing is called Click Eco-System and enables our customers to have full visibility and control of their key supply chain pillars using the power of a click.

Do you want to learn more how you can fully adopt these logistics and supply chain trends from 2022 and beyond? Get in touch today so you won't miss out on these great changes in the trade landscape.